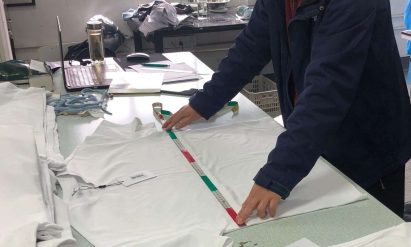

Overview

The During Production Inspection (DPI), also known as In-Process Inspection, is a quality inspection conducted when 20-50% of production is completed. It ensures that the manufacturing process remains aligned with approved product specifications, quality standards, and client expectations. DPI focuses on verifying product consistency, identifying defects, and assessing production processes, helping to detect issues before they escalate.By conducting DPI at this stage, manufacturers can implement timely corrective actions, ensuring that quality standards are maintained throughout the production cycle. This inspection helps prevent widespread defects, reduces rework costs, and ensures that the final batch meets customer requirements before mass production is completed.