Overview

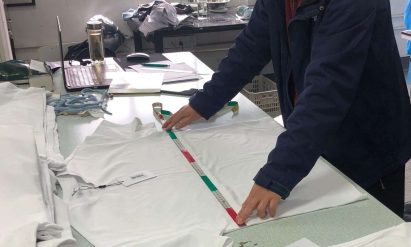

The Defect Sorting Inspection (DSI), also known as 100% Inspection, is a quality control process designed to identify and remove defective products before shipment. Unlike random sampling inspections, DSI involves a full inspection of all goods to ensure that only defect-free products are delivered to customers. During this process, inspectors examine each unit and classify defects into minor, major, and critical categories, removing all non-conforming products from the batch. This inspection is particularly useful when previous quality checks have detected a high defect rate, or when buyers require strict quality control measures to minimize the risk of defective goods reaching the market. By conducting DSI, businesses can significantly reduce returns, improve customer satisfaction, and ensure compliance with strict quality standards.