What is Quality Inspection?

Quality inspection is the process of checking, measuring, or testing product characteristics to ensure they meet predetermined requirements. In international trade, buyers typically require inspection services to verify whether products meet the agreed specifications and quantities.

To ensure the best results, companies can choose to collaborate with trusted third-party inspection service providers. Inspectors follow a pre-established checklist based on the product and customer specifications, verify whether the product meets the requirements, and compile the results into a report.

Quality Inspection vs. Quality Control

Quality inspection is a component of quality control, but it does not directly influence the production process. Quality inspections are typically conducted at various stages of production to detect and correct deviations, ensuring the final product meets quality standards.

Quality control, on the other hand, encompasses not only inspection activities but also process monitoring, data analysis, and improvement measures.

Quality inspections provide valuable feedback, which quality control uses to adjust and refine the production process, ensuring that product quality remains consistently in line with established standards. Both work in tandem to enhance the quality of products and services.

Types of Quality Inspection Services

Investing a few hundred dollars in quality inspections when importing goods from China can be one of the smartest investments. This can help you avoid weeks of delays caused by potential quality issues and product rework. However, knowing when and how to conduct these inspections can be somewhat complex.

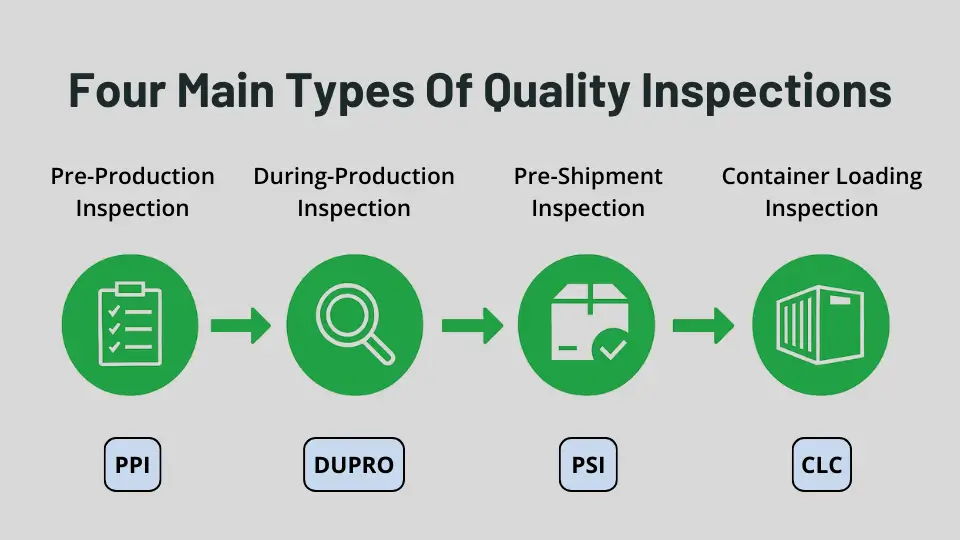

Generally, there are four main types of quality inspection services available:

Pre-production inspection (PPI) is the process of evaluating the quality and quantity of raw materials and components before production begins. This inspection helps ensure that suppliers use the correct materials and follow the proper processes, preventing quality issues caused by substandard materials. Additionally, PPI helps identify potential production process problems.

Pre-production inspections allow businesses to detect issues early, before it’s too late. By implementing PPI, companies can ensure that suppliers adhere to the agreed production processes, helping to avoid delays in the supply chain and product delivery. After all, no one likes to miss deadlines.

During Production Inspection (DUPRO)

During production inspection (DUPRO) is performed throughout the production process, particularly for products that undergo continuous production and for companies with strict delivery deadlines. This inspection helps follow up on any quality issues identified during the pre-production inspection.

Typically conducted when 10-15% of the production is completed, DUPRO provides an early indication of the product’s quality. After any issues are corrected, another inspection is performed to ensure the problems are resolved. Inspectors generate a detailed report with relevant images, providing comprehensive information and data.

Conducting inspections early in the production process, especially in the early stages, helps prevent quality issues from being discovered late in the process. By identifying and addressing potential problems promptly, businesses can avoid rework and delays, ensuring on-time delivery.

Pre-shipment inspection (PSI) is a quality inspection conducted before the shipment of goods. The purpose of PSI is to confirm that the product’s specifications and quality meet the buyer’s requirements and comply with the purchase order or letter of credit.

PSI is typically scheduled once 100% of the production is completed and at least 80% of the packaging is finished. As such, it is often referred to as the Final Random Inspection (FRI). PSI uses random sampling to examine the goods, testing them against Acceptable Quality Limits (AQL) or customer-specified standards.

PSI helps overseas buyers confirm that the products meet international standards, reducing the risks of quality issues and fraudulent transactions. It is one of the most commonly used types of quality inspections, as it occurs at the final stage before shipment, making it difficult for suppliers to conceal quality problems.

Container Loading Inspection (CLC)

Container Loading Inspection (CLC) is conducted once the goods have been produced, packaged, and loaded into the container, ready for shipment. The primary purpose of CLC is to verify that the product’s specifications, labels, barcodes, and packaging materials meet the buyer’s requirements.

This inspection is useful in specific cases, such as when the buyer has precise loading instructions or when the packaging method is non-standard. It is also suitable for situations where the buyer does not fully trust the supplier, confirming that the correct types and quantities of goods are being shipped.

CLC helps ensure the proper loading of goods. Improper loading or an unbalanced container may lead to product damage or safety hazards during transportation. Conducting CLC helps prevent these issues and ensures the goods are securely loaded.

For more detailed information, you can refer to this article on steps to follow during a container loading inspection.

Conclusion

Each type of quality inspection service serves a unique purpose at different stages of the production process. By strategically scheduling these inspections,importers can maintain product quality while reducing potential risks and losses.

Whether you are working with suppliers in China, Vietnam, or other regions, choosing the right quality inspection service is essential for securing important protection for your goods.

QCC INSPECTION is a professional third-party inspection company that can assist you with any of the above types of quality control inspections in China, Vietnam, and other locations. Contact us now to learn how we can help you ensure your production meets the highest standards.

April 05,2025

April 05,2025