What Should Be Ready Before You Book a Container Loading Inspection?

When booking a container loading inspection, it’s crucial to ensure everything is prepared in advance for a smooth process. Here are the key steps to take:

Ensure the Shipment is Fully Packed and Ready

Make sure all items are packed according to the order specifications, with proper packaging to protect the goods during transport.

Collect All Goods in One Location

If the shipment consists of items from different suppliers or factories, ensure they are gathered in one place to avoid delays and verify completeness.

Confirm the Container is Arranged for Loading

Confirm that the container is available, clean, dry, and suitable for loading the goods.

Prepare a Clear and Complete Packing List

Have a clear packing list that matches the order and outlines the quantity, specifications, and model of each item.

Coordinate with the Supplier or Factory

Ensure all goods from different suppliers or factories are packed and ready in one place according to the agreed schedule.

Confirm the Inspection Timing and Logistics

Confirm the date, time, and logistics for the inspection with the inspection company, ensuring everything is ready for a smooth process.

Steps Should Be Followed During a Container Loading Inspection

Inspect the Container Condition

Before loading, ensure the container is free from deformation, cracks, or severe rust. The interior should be dry and odor-free, the floor should be intact, and the door locks and seals should be functioning properly to prevent water ingress or damage during transportation.

Verify the Goods and Quantity

Confirm that the goods match the order and packing list, not only by counting but also by checking the specifications, models, and appearance to avoid loading incorrect goods or missing products.

Inspect Packaging and Labels

Ensure the packaging is in good condition, without damage, deformation, or contamination. Verify that the outer carton labels, barcodes, and marks are clear and accurate, in compliance with customer and logistics requirements.

Supervise the Loading Process

Ensure that the goods are loaded according to the predetermined plan, avoiding heavy items crushing lighter goods, uneven stacking, or deformation. Also, check that the goods are securely fastened to reduce the risk of shifting or toppling during transport.

Verify Sealing and Seal Numbers

After loading, confirm that the container seal is properly applied and record the seal number to ensure secure transportation.

Document the Loading Process

Take photos or videos of the loading process, including the placement of goods, container numbers, and seal numbers for future reference.

Other Inspections You Can Conduct

While container loading inspection can identify issues during loading, relying solely on this step doesn’t guarantee product quality. Conducting inspections during production can help detect and correct issues before they lead to delays or losses.

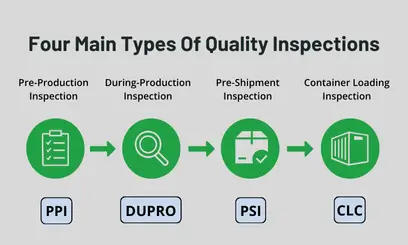

Here are a few common types of inspections:

Initial Production Check (IPC): Conducted at the start of production to identify potential quality issues early and reduce risks during production, ensuring that manufacturing meets customer requirements.

During Production Inspection (DUPRO): Conducted at the mid-production stage to monitor product quality at different stages, detect and address defects promptly, and ensure the production meets the required standards.

Pre-Shipment Inspection (PSI): Conducted when 80%-100% of production is completed to check the overall quality, specifications, and functionality of the products, ensuring they meet order requirements and preventing defective products from reaching the market.

Production Monitoring (PM): On-site inspectors provide daily supervision to track production progress and quality status in real-time, promptly identifying and addressing issues to ensure smooth production.

Conclusion

By combining these inspections, companies can better control product quality at different stages and avoid quality problems that could arise only at the loading stage, improving the reliability of the entire supply chain.

Founded in 2010, QCC INSPECTION is an independent inspection company in China. Over the past decade, we have worked with more than 3,000 clients, providing a wide range of services including supplier audits, quality inspections, container loading supervision and laboratory testing.

With a skilled team of more than 200 experienced inspectors and auditors, we are your reliable partner in China, ensuring seamless control at every stage of your supply chain. If you have any questions, please feel free to contact us.

April 05,2025

April 05,2025