Many businesses sourcing from China face the following challenges:

Unclear inspection standards lead to misunderstandings between suppliers and customers.

For example, a customer may believe surface scratches on a product are a clear defect, but the supplier considers them acceptable, leading to disputes.

Vague or generalized inspection content that is difficult to implement during actual inspections.

Some businesses instruct suppliers to deliver “high-quality” products but fail to specify what exactly constitutes “high quality” (e.g., acceptable dimensions, the number of permissible surface scratches), leading to inconsistent inspection standards.

Critical quality points are often overlooked, only to be discovered after the products are delivered to the customer.

For instance, a customer purchasing electronics may not specify the need to check charging ports or LED indicator functionality, only to find a significant number of defective products after delivery, leading to after-sales complaints.

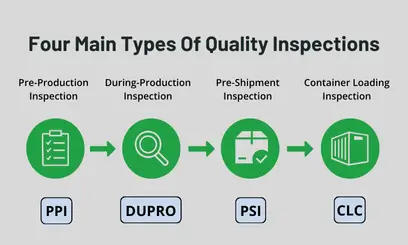

In additon, an effective QC checklist should include:

- Clear standards for dimensions and allowable tolerances

- Specific requirements for appearance and defect allowances

- Methods for testing functionality and performance, with clear acceptance criteria

- Detailed requirements for packaging, labelling, and barcodes

- Clear verification methods for regulatory compliance (such as CE, UL,and RoHS standards)

- Special customer requirements and custom specifications

Having such a detailed and specific QC checklist can help you:

- Clarify communication with suppliers and avoid misunderstandings during inspections

- Ensure each inspection is thorough and consistent, minimizing product quality risks

- Detect issues early and require suppliers to make improvements, preventing potential defects from reaching the market.

Quality Control Real-World Examples

Here are real-world cases that clearly demonstrate the value of quality control:

Case 1: Timely Detection of Faulty Electronic Product Connectors

An American customer who purchased Bluetooth headsets in Shenzhen found that about 15% of the products had problems with the charging port. After receiving our pre-shipment inspection report, he promptly asked the supplier to rework the product, effectively avoiding tens of thousands of dollars in returns and after-sales compensation losses.

Case 2: Quick Resolution of Textile Color Difference Issues

A European customer sourcing high-end shirts from China encountered noticeable color differences in the fabric. Through our during-production inspection, the issue was detected early, and the customer quickly adjusted the dyeing process, preventing large batches of defective products from entering the market, thus protecting their brand reputation and market performance.

Case 3: Early Detection of Structural Safety Risks in Furniture

An Australian client purchasing outdoor chairs from China found, through our in-process inspection, that the welding on the chair’s support structure was weak, presenting a significant safety risk. The customer immediately required the supplier to reinforce the welding, preventing potential consumer safety issues and related legal risks.

Case 4: QC Checklist Helps Customer Avoid Watch Glue Separation Issues

A Canadian customer sourcing watches from China had previously worked with other inspection companies that lacked a detailed QC checklist. These companies only conducted basic appearance and functionality checks, overlooking the adhesive strength of the bond between the watch case and watch dial(back). When the customer received the products, many watches had glue separation issues, leading to significant damage to their brand reputation.

After switching to our services, we created a detailed QC checklist addressing the glue bond strength, requiring inspectors to conduct specific tension tests. Since implementing this checklist, the customer has never encountered this issue again, and their brand reputation was quickly restored and steadily improved.

April 05,2025

April 05,2025