At QCC INSPECTION, we adhere to globally recognized inspection standards to ensure your products meet the highest levels of quality, safety, and compliance. These standards guide our inspectors in evaluating diverse product categories, helping you reduce risks, meet market requirements, and build trust with your customers.

Key Inspection Standards We Follow

General Industry Standards

Our inspections align with established quality control frameworks that apply across all product categories.

- ISO Standards: We use ISO 2859 (Sampling Procedures for Inspection by Attributes) and ISO 9001 (Quality Management Systems) to ensure consistent inspection processes.

- ASTM Standards: We follow ASTM guidelines for product safety and performance testing.

- CE Compliance: We verify compliance with CE marking requirements for products entering the EU market.

AQL Sampling Method

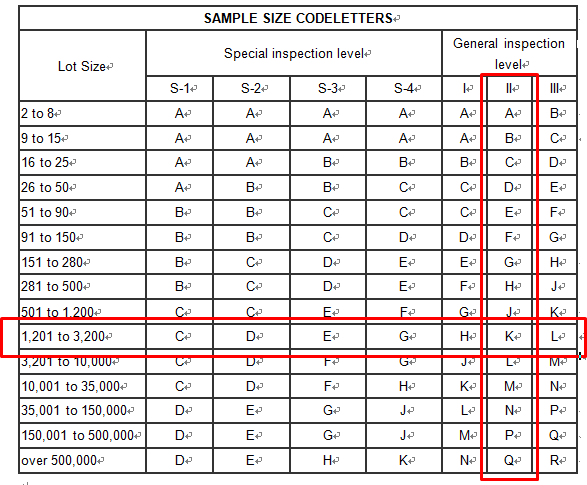

The Acceptable Quality Limit (AQL) is a statistical sampling method used to determine the sample size for inspection and set the maximum allowable defects. This structured approach ensures a statistically valid assessment of product quality.

Common AQL Levels We Use:

- Critical Defects (AQL = 0): No tolerance for severe safety risks or regulatory violations.

- Major Defects (AQL = 2.5): Standard for most consumer products; allows minimal functional defects.

- Minor Defects (AQL = 4.0): Tolerance for minor cosmetic issues that do not affect usability.

AQL Sampling Process:

- Determine Lot Size: Identify the total production lot size, which impacts sample size selection.

- Select AQL Levels: Choose AQL levels based on product type and quality requirements.

- Determine Sample Size Using AQL Table: Refer to the AQL table to select an appropriate sample size.

- Inspect and Classify Defects: Identify defects and categorize them as Critical, Major, or Minor.

- Decision Making: Accept or reject the lot based on the number of defects found.

This method allows us to provide reliable and consistent quality assessments while optimizing inspection time and costs.

Use our AQL Calculator to easily calculate the exact sample size and acceptance limits you need.

Checking Criteria

Our inspection process follows detailed checking criteria tailored to the product category, ensuring comprehensive evaluation.

- Specification Check: We verify that the product’s dimensions, weight, material composition, and key features meet client specifications.

- Functionality & Performance Testing: We assess the product’s functions and performance metrics to ensure reliability.

- Safety Checks: We evaluate the product against electrical, mechanical, and chemical safety standards.

- Visual Inspection: We identify surface defects, appearance issues, and check labeling accuracy.

Detailed Defect Classification

We categorize defects into three main levels based on their severity and impact:

- Critical Defects (AQL = 0):

- Definition: Severe issues that pose safety risks or violate legal requirements.

- Examples: Exposed electrical components, sharp edges, toxic substances.

- Impact: Immediate rejection due to potential safety hazards.

- Major Defects (AQL = 2.5):

- Definition: Issues that impair the product’s primary function or significantly reduce its market value.

- Examples: Non-functioning parts, broken components, poor alignment.

- Impact: High risk of customer dissatisfaction and product returns.

- Minor Defects (AQL = 4.0):

- Definition: Minor imperfections that do not affect functionality but may impact the product’s appearance.

- Examples: Small scratches, slight color variations, loose threads.

- Impact: Generally acceptable, but may influence perceived quality.

This classification helps prioritize corrective actions, ensuring the most critical issues are resolved first.

Common Questions About Our Inspection Standards

Q1: What is AQL, and why is it important?

AQL (Acceptable Quality Limit) is a statistical tool used to determine the sample size for inspection and the maximum number of defects allowed. It helps balance thorough inspection with efficiency, providing a reliable assessment of product quality.

Q2: What are the typical AQL levels used?

For most consumer products, we use:

- AQL 0for Critical Defects (no tolerance for severe issues).

- AQL 2.5for Major Defects (standard level).

- AQL 4.0for Minor Defects (tolerance for minor cosmetic issues).

Q3: How do you decide whether to accept or reject a lot?

We refer to the AQL table to determine the sample size and acceptable defect limits. If the number of defects exceeds the allowable limit, the lot is rejected.

Q4: Can you customize the inspection criteria based on our product requirements?

Yes, we tailor our inspection criteria based on client specifications and product type, ensuring a relevant and thorough evaluation.

Why Our Inspection Standards Matter

- Consistency: We provide uniform quality assessments across all inspections, reducing variability.

- Compliance: Our adherence to recognized standards helps you meet international regulatory requirements.

- Risk Reduction: Early identification of defects minimizes rework, recalls, and production delays.

- Customer Satisfaction: High-quality products that meet expectations lead to increased trust and loyalty.

Get Started with QCC INSPECTION Standard-Compliant Services

Ensure your products meet international quality and safety standards with our reliable inspection services. Contact us today to learn more.

Products

Need more information?

QCC SAMPLE REPORT

For sample reports or custom checklists, please contact us – we're here to assist you.